Francis Vonder Haar

Vice President and General Manager, ImagingIf your organization is one of the over 50% of hospitals who expect capital spending to be flat in 2024, a strategy for safely and cost-effectively adding years of performance to equipment nearing End of Service Life is critical. But not all end-of-life equipment is created equal: when does it make sense to replace aging equipment vs. extending its life? This blog will address the different stages that comprise End of Life, a checklist for understanding how to evaluate equipment for extension, and options for maintaining equipment after manufacturer end of guaranteed support.

What is End of Life?

“End of Life” as a concept can be confusing because the term is often used interchangeably with more than one stage in a product’s life cycle, as outlined below:

End of Production: The product is no longer produced, but the manufacturer may continue to sell pre-existing inventory and will be required to maintain replacement parts for seven years

End of Guaranteed Support: Manufacturers will no longer maintain spare parts, provide training, technical support or cover these products under service contracts but may provide service on a case-by-case basis

End of Support: All support from the manufacturer ceases, including on-site service and remote monitoring, technical support, access to manuals and software updates

Manufacturers must provide notice of End of Support in advance, usually 12-18 months from End of Guaranteed Support, which allows hospitals to explore options, including budgeting to update to the manufacturer’s latest technology. But how do leading systems determine when, and which equipment, to extend? And for how long?

For guidance, historically, systems turned to depreciation tables for medical devices detailed in the American Hospital Association’s “Guidelines for Useful Life.” In recent years, however, CFOs and financial leadership have responded to challenging capital and operating margin environments by increasingly pursuing the option of extending service life beyond the published recommendations. With that mandate, it becomes important for HTM and supply chain leaders who are responsible for uptime and clinical stakeholder satisfaction to understand how to accomplish this safely.

Which Equipment to Consider Extending?

Imaging equipment entering End of Guaranteed Support can be an attractive category considering the sizable investment to replace this equipment. For popular models from leading manufacturers, access to aftermarket/refurbished parts and trained service technicians needed to maintain and repair the equipment most likely exist, but when considering extending an asset, first confirm that:

- A healthy marketplace for high-quality replacement parts and preventative maintenance kits exists for your make and model

- A qualified service network is available within your market, including access to remote monitoring

- The asset has been well-maintained with an average/nationally benchmarked failure rate to date

- Other considerations may include cybersecurity risks for connected devices no longer eligible for OEM software updates/patches, so be sure to confirm what the manufacturer’s plan is for technology and consult with your IT leadership as part of the risk assessment process. Assets at End of Support will not receive any technological/software support and cybersecurity liabilities transfer to the health system from the manufacturer.

As equipment that is not directly life-sustaining, the inherent risk of extending imaging equipment is downtime, which does impact patient throughput and revenue. However, when prioritizing patient safety, imaging equipment can be a more viable opportunity than a modality like ventilators for hospitals to extend the life of well-maintained devices beyond the manufacturer End of Guaranteed Support.

Options for Extending Service Coverage

Transitioning off a warranty or extended full-service contract can give supply chain and HTM leaders anxiety, especially for aging equipment. To mitigate this risk, an extended service agreement with capitated spend can help ensure budget predictability and deliver high-quality service from technicians experienced on your equipment. Flexibility is also key, so that if an asset begins to require more frequent repairs, it can be removed from the agreement and decommissioned.

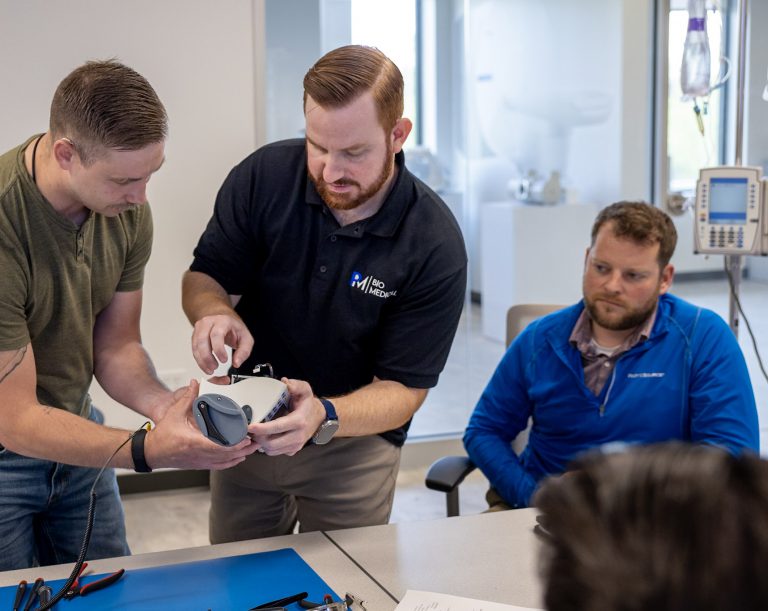

How can you confidently determine when extending is the best solution vs. disposition and/or replacement? Leveraging a third party who understands the parts and service market situation for your assets is key. These insights are central to a strategic partnership in not only identifying which equipment to extend, but also the recommending of qualified service providers with experience on your assets and access to 4 million parts to handle ongoing service needs after the manufacturer ceases service support.

In conclusion, manufacturer end of support does not have to mean end of the line for your investments in imaging equipment. As access to capital tightens and operating margins compress, financial leaders are increasingly turning to HTM leaders to safely extend the life, and ROI, of equipment and defer replacement capital purchases. For HTM leaders, this means evaluating the device history, ensuring access to replacement parts and a trained service network to help maintain the device. To manage risk and capitate budget, consider a flexible service agreement such as a PartsSource Repair and Service Agreement to help keep your equipment up and running past End of Guaranteed Support.